Choosing End Mill Bits

end mill bit

End mills are milling cutters that might be referred to as slot drills or cutters. They are usually used in industrial milling applications. End mills remove material, and you can create multi-dimensional shapes and profiles with them. End mills, unlike regular drill bits, can cut in all directions. Machinists use them for side milling, face milling, slot milling and plunging.

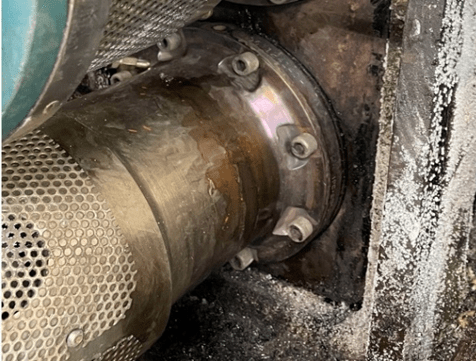

Parts of an End Mill Bit

An end mill bit consists of a shank – the part that is held by the milling machine, a helix angle, flute, outside diameter, cutting length and overall length.

The helix angle and the angle of the cutters and the flute is the section just below the cutter. The outside diameter is measured from the very outside of one cutter and across the center to the very outside of the opposite cutter.

End Mill Bit Options

When choosing end mills, you have several options, including:

- High-speed steel bits. These don’t cost much, but are versatile and tough. They absorb shock well and have increased heat and wear resistance.

- High-speed cobalt bits. High-speed cobalt bits have some of the same features of high-speed steel bits, with the main feature being that they have increased heat and wear resistance.

- Powdered metal bits. These bits cost more than high-speed steel and high-speed cobalt bits, but they are harder than high-speed bits. They are also versatile and good at resisting shock. If you are milling Inconel, Waspalloy or other high-temp alloys, choose a powdered metal bit.

- Solid carbide bits. Solid carbide bits are the hardest material that milling bits can be made of. They cost considerably more than powdered metal and high-speed end mill bits. They are also more brittle than the other bits, but last longer as long as you properly care for them. Solid carbide bits have faster operating parameters than high-speed bits – they can mill up to 2.5 times faster.

- Coated or uncoated bits. Aluminum titanium nitride coated end mill bits also have a high hardness characteristic. Using these, you will have less of a chemical reaction between the end mill and your workpiece.

- Square end vs. ball nose bits.

- Center cutting vs. non-center cutting bits.

- Single end vs. double end bits.

- Weldon shank vs. plain shank bits. Weldon shanks have one or two flats for set screws and are good to use in roughing conditions, while plain shank bits are good for small diameters and have an adjustable tool length. Plain shank bits are better for precision clamping and shrink fitting.

When choosing a bit, consider your project, including the material, the tool path, whether you have a manual or power feed, and whether the application is wet or dry.

When choosing an end mill, you should also consider several factors, including the number of pieces you will be producing and the machine’s specifications, including age, condition, style, strength, horsepower, spindle speed and rigidity.

The machine also determines which types of bits you purchase.

Types of Milling

Choosing the correct end mill and end mill bits also depends on the type of end milling you provide. You can choose bits for side milling, face milling, slot milling, plunge milling and ramping.

You can also choose bits for center cutting or non-center cutting. Center cut bits are the most common types. When using a center cut end mill bit, the bit plunges into the material just as a regular drill bit would. Center cut bits are also used for surface milling. Non-center cut milling bits are only used for side milling.

Choosing the Number of Flutes

The number of flutes on an end mill bit depends on what you are milling, the type of milling you are doing, and the size of your project. The fewer flutes on an end mill bit, the more efficient chip removal is. However, if you want a better surface finish, you need more flutes. End mill bits with two and four flutes are the most common.

Single or Double End Mill Bits?

The most common type of end mill bit is a single end. The double-end mill bit has a cutting bit on both ends of the tool. Using double-end bits can save money on tools, but the end mill might not have enough clearance for a double-ended bit.

Ball or Square-Nosed End Mill Bits?

Square-nosed end mill bits are more common than ball-nose end mill bits. A ball-nose bit creates a rounded cut for contoured surfaces. The round-nose bit is ideal for milling in molds and dies or to add a radius between perpendicular faces. Additionally, ball-nose bits are only for finishing and not roughing out a project.

When You Need a Roughing End Mill

Roughing end mill bits remove large amounts of material very quickly.

WHY A ROUGHING END MILL?

Roughing end mills quickly remove large amounts of material using a wavy tooth form cut. The bit produces many small chips, which causes the finished surface to be rough. Roughing end mill bits are always made from cobalt or powdered metal because of the speed they need to take off a lot of material at once.

End Milling Formulae

When using an end mill, you might need to figure out certain specifics. The formulae for these are:

SFM: surface feet per minute; RPM: revolutions per minute; F: feed in inches per minute

Ft: Feed per tooth; D: cutting diameter; T: number of teeth

The formulae are:

- SFM equals D times RPM times 26.

- RPM equals SFM times 3.82 divided by D.

- F equals Ft times T time RPM.

- Ft equals F(Feed) / T times RPM.

Diagnosing End Mill Bit Issues

Tools break. However, if you notice that tools break when they’re new or too often, you might have to adjust the end mill.

Tools Break Frequently

- The feed is too heavy. Reduce the feed rate.

- The cut is too heavy. Make narrower and shallower cuts.

- The tool has too much overhang. Use a shorter tool and insert the shank into the end mill deeper.

- Tools wear out too fast, then break. Regrind the tool sooner.

Tools Wear too Fast

- Decrease the spindle speed.

- Use a coated tool on hard work material.

- Use high-pressure coolant and change the chip size if the tool is recutting chips.