Choosing the Proper Tap

Metalwork

Many industries use taps, though the most common industry is machinists. You can also find taps in the automotive and electrical industry. While the latter may not have machinists, the technicians are taught to use taps to bore holes or straighten threads. Whether you are new to using taps or have been using them for years, you will find tips in this training module to help you choose the proper taps.

Parts of a Tap

When choosing a tap, you must know certain measurements based on the project you are working on and the tools you are using, including:

- Square across flat. This is the part that goes into the tool you use to turn the tap. It is part of the shank and is square.

- Shank diameter. This is the diameter (width) of the shank. A tap with a smaller shank diameter will twist or break if the metal is too hard. Smaller-sized taps may have smaller shank diameters.

- Recess diameter. The recess diameter is smaller than the shank diameter and is measured below the shank, where the tap narrows.

- Flute. The flute is a hollowed-out section of the business end of the tap. For blind hole taps, the flute funnels the metal chips out of the hole, so the threads stay clean. A tap can have one to four flutes.

- Pitch. The distance between two threads.

- External center (male). The unthreaded point of the tap.

- External thread diameter.

- Chamfer lead length. The first few threads of the tap. The number and size of the chamfer lead depend on the type of tap.

- Thread length. The length of all of the threads.

- Recess length. From the top of the external center to the bottom of the shoulder above the recess diameter.

- Shank length. From the top of the square across flat to the bottom of the shank diameter before it forms the shoulder leading to the recess diameter.

- Square length. The length of the square that fits into the turning tool.

- Overall length.

- Helix angle. The angle of the flute.

- Spiral point length.

- Spiral point angle. The measurement from the tip of the tap to the outside edge of the spiral point.

- Chamfer lead angle. The angle of the pointed end of the tap.

Major vs. Minor Diameter

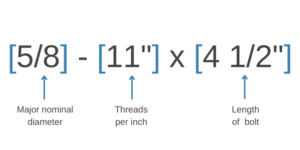

The major diameter is measured from the outside of the threads to the opposite outside side of the threads, while the minor diameter is measured from the bottom or inside of the thread to the bottom or inside of the thread on the opposite side.

What is Thread Pitch?

The thread pitch is the measurement from the center of one outside thread to the center of the next outside thread. To calculate the thread pitch on an imperial tap, divide 1 by the threads per inch. If the tap has 20 threads per inch, 1/20 equals .050”.

If the tap is a metric tap, the formula is M6 x 1.0 for a pitch of 1 mm.

What are Flutes?

The flute design dictates what happens to the chips while you are using the tap. You must have room for the chips to “escape.” If the flutes are not large enough, the chips won’t curl, and you’ll need more power to form the thread. The smaller the tap, the less room you have for flutes. Thus, a 5/16” diameter tap doesn’t have enough room for four flutes if it has unified coarse threads.

The flutes are the smooth channels on the tap. A tap could have two, three or four flutes to evacuate chips. The more flutes a tap has the more teeth for cutting action.

How to Select the Proper Tap

The first decision you need to make when choosing a tap is whether the hole is a through hole or a blind hole. A tap for a through hole has a flat bottom, while the tap for a blind hole has a pointed bottom.

Taps with tapered leads are best for materials that are more difficult to mill. Though they have a point at the end of the tap, they are not recommended for blind holes because of the taper of eight to nine threads.

A tap with a plug lead of three to five threads can be used for hand or machine tapping and is the most common tap you’ll find in tap kits. You can use it for most through holes and blind holes.

A tap with a bottoming lead of one to two threads is used for blind holes. You’ll get threads closer to the bottom of the hole. This type of tap is not recommended for starting new threads.

Classes of Taps

The various classes of taps include:

- Straight flute taps. These taps are used to tap blind holes and come with different helix angles. Use a 40-degree helix angled tap for tapping through softer metals and a 15-degree helix angled tap for tapping through tougher materials. As you are using the tap, it feeds the chips through the flutes and out of the top of the hole.

- Spiral flute taps. These taps pull the chips out through the flutes and the top of the hole. They’re recommended for blind holes or holes where you have to pass by grooves and/or keyways.

- Spiral point taps. These are recommended for tapping through holes. It pushes the chips ahead of the tap, rather than storing them in the flutes and then ejecting them out of the top.

- Threadmill taps. These taps create threads by displacing material rather than cutting it. They can be up to three times faster than cutting taps and produce a stronger thread form. They are recommended for materials up to 25 Rc.

The types of threads include:

- Unified coarse thread (UNC).

- Unified fine thread (UNF).

- Unified extra fine thread (UNEF).

- Unified special thread (UNS).

- Metric coarse thread (M).

- Metric fine thread (MC).

H Limits

The “H” number defines the pitch diameter of the tap. H1 taps have a pitch diameter from .0000” to .0005”. H2 taps range from .0005” to .0010”. H3 ranges from .0010” to .0015”. Finally, H4 taps range from .0015” to .0020” and over.

Metric threads are denoted by the letter “M,” followed by the pitch. For example, M8 x 1.25. A 4H is a tight tolerance, which is similar to the unified 3B class of fit. A 6H is similar to the unified 2B class of fit.

Types of Taps

Various types of taps include:

- Hand taps.

- Spiral point taps.

- Spiral flute taps.

- Thread formers.

- STI.

- Pulley / extension taps.

- Combination drill / taps.

- UNC, UNF, UNS and metric taps.

Visit Abolox for Taps

When you need various types of taps, visit Abolox. We carry only high-quality brands of taps for blind holes and through holes to help you make or cleanup threads in metal items, including vehicle parts, electrical parts, and structural parts made of metal.