Case Study: Adjustable Spot Cooler Saves Thousands of Dollars in the Textile Industry

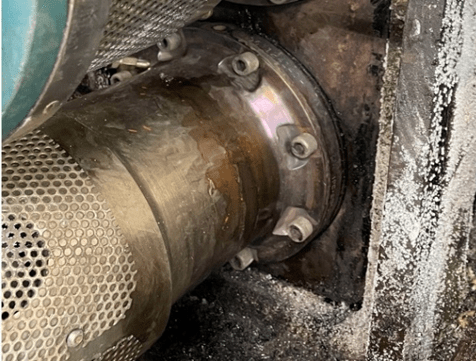

A few months ago I got a call from a major producer of high-performance knitted products who operates 128 Spindle motors on circular sock machines (CSM) that require couplings. These couplings use hi-speed, hi-temperature bearings that have been failing regularly, prior to the predicted run life. This was resulting in loss of production while the CSM is down and the bearings are replaced, repair costs associated with refurbishing the failed CSM bearing include labor, new bearings, lost production, etc. The average cost of a failed CSM bearing including lost production was around $1925.00 and on average they were seeing 180 premature failures each year.

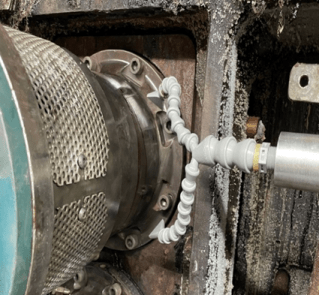

My recommendation was using a 3925 Adjustable Spot Cooler System with the dual outlets to spread the cooling around the bearing. They had tried fans and electric blowers and they noticed no benefits. How ever when they placed the 3925 on the largest trouble maker that was burning bearings at the highest rate they noticed a prolonged lifetime of over 260%!!!!

The enhanced run life of the CSMs was noticed immediately as the non-cooled CSM bearings continued to fail at a much higher rate when compared to the positions with the Exair Spot Coolers installed.

Based on the average cost of a failed CSM bearing including lost production ($1925.00) and an average of (180) premature failures each year, their estimated annual savings using the Adj. Spot Cooler is $346,500.00 on just the 12 high fail rate machines they have put these on to date. They are expecting to place a 3295 on every CSM within 5 years focusing on the high fail rate machines first.

If you think the Adjustable Spot cooler can help your process, give us a call or shoot us an email!

Jordan Shouse

Application Engineer

Send me an Email

Find us on the Web

Like us on Facebook

Twitter: @EXAIR_JS