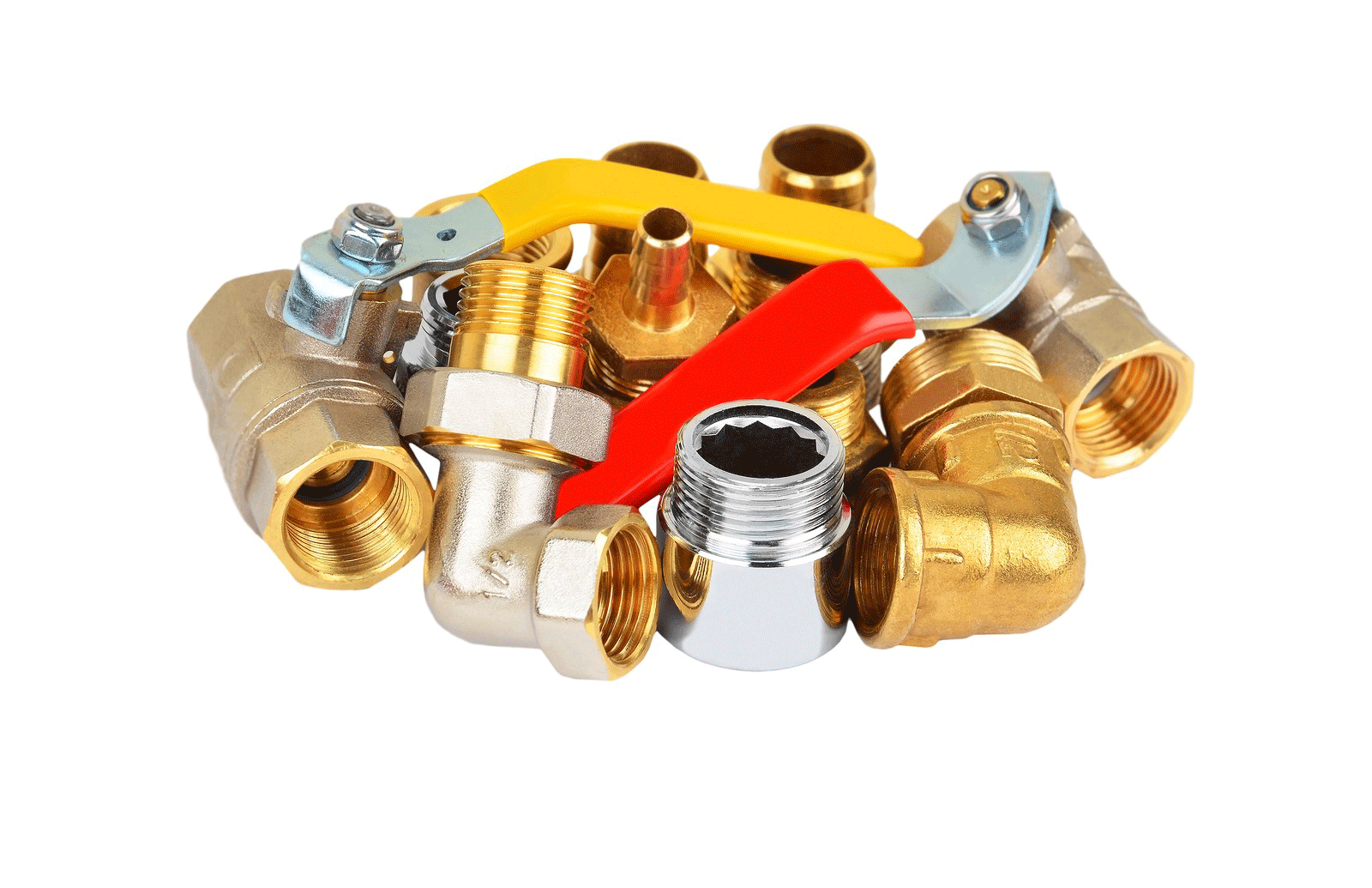

What to Think About When Buying a Valve

Consider Valve Function

Valves can serve many different purposes- control of flow, regulating pressure, on/off,

temperature regulation, and many more. Each function requires different valves and configurations.

Review the Media Process

What is the process medium of what you are putting your valve on? For instance, if a

valve is on -320F liquid nitrogen, it requires different seats, seals, and bonnets

than a valve that is on 70F potable water.

Double Check the Valve Size Specifications

This may sound quite elementary but many people think that the valve that they need

should be line size. Sometimes purchasing a valve that equals line size makes a lot of

sense but other times, you can specify a smaller (less expensive) valve that will do the

exact same thing as a valve that equals line size.

Valve Automation…is it Necessary?

Do you need an automated or pneumatic valve? What type of actuation- pneumatic, electric?

Double acting, fail open, fail close? If pneumatic, how much air do you have

available for actuation- 60 or 80 psi? Would you like a solenoid or limit switch?

All of these questions (and more) are questions you should consider while specifying

and purchasing your valves. We realize that many individuals do not feel comfortable

knowing exactly the right questions to ask to assure that their valve will be the

exact right valve for their application. Since realizing this years ago, we have

offered our services to assist customers to spec and purchase the perfect valve for

their application.

Contact ValveMan today for assistance with your application!