How to Know When It’s Time for a Moyno Pump Replacement

Moyno pumps are renowned for their reliability and efficiency in various industrial applications. However, like any mechanical equipment, they have a lifespan and may require replacement over time. Understanding when it’s time for a Moyno pump replacement can save you from costly downtime and ensure optimal performance in your operations. This article outlines key indicators to help you determine when it’s time to replace your Moyno pump.

Signs Indicating a Need for Replacement

- Decreased Performance

- One of the first signs that your Moyno pump may need replacing is a noticeable drop in performance. If you observe reduced flow rates or pressure, it may indicate that the pump is struggling to operate efficiently. This can lead to operational inefficiencies and increased energy costs.

- Unusual Noises

- A well-functioning Moyno pump should operate smoothly and quietly. If you start hearing strange noises such as grinding, rattling, or excessive vibrations, it could be a sign of internal wear or damage. Ignoring these sounds can lead to further deterioration and eventual failure of the pump.

- Frequent Maintenance

- While regular maintenance is essential for any pump, if you find yourself performing repairs or maintenance more frequently than before, it may be time for a replacement. An increase in maintenance frequency often indicates that the pump is nearing the end of its useful life.

- Visible Wear and Tear

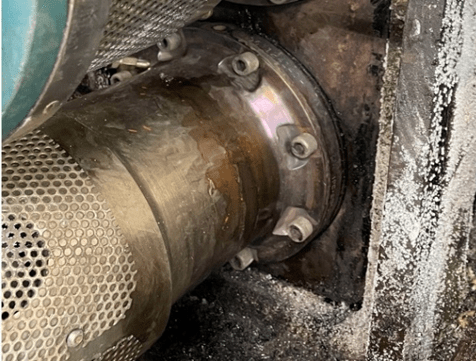

- Regularly inspect your Moyno pump for signs of physical wear and tear. Look for cracks, leaks, or corrosion on the pump casing and components. Significant visible damage can compromise the pump’s functionality and safety, signaling that a replacement is necessary.

- Increased Energy Costs

- If you notice a spike in energy consumption associated with your Moyno pump, it could be struggling to perform its duties effectively. Aging pumps often require more energy to operate, which can lead to higher operational costs. Evaluating the energy efficiency of your pump can help determine if a replacement is warranted.

Evaluating Replacement Options

When considering a Moyno pump replacement, it’s important to evaluate your options carefully. Here are a few tips for making an informed decision:

- Consult with Experts: Reach out to professionals who specialize in pump systems. They can provide insights into the best replacement options based on your specific needs and operational requirements.

- Assess Compatibility: Ensure that the new pump is compatible with existing systems and processes. Consider factors such as capacity, material compatibility, and installation requirements.

- Plan for Downtime: Replacing a pump can lead to temporary downtime. Plan for this by scheduling the replacement during off-peak hours to minimize disruptions to your operations.

Conclusion

Recognizing the signs that indicate a need for a Moyno pump replacement is essential for maintaining efficiency and avoiding costly disruptions. By paying attention to performance issues, unusual noises, maintenance frequency, visible wear, and energy costs, you can make informed decisions about the health of your pump system. With careful evaluation and planning, you can ensure that your operations continue to run smoothly and effectively.