Types of Alloy and the Properties of Alloy Steel

- Previous blog

- Next blog

- Huyett Marketing Department

- 04/01/2021

- Updated 08/10/2023

mechanical properties of the metal in question. Some applications require metals that are machinable and ductile, while others need hard metals with significant corrosion resistance, and still others require any number of property combinations, depending on the application setting.

alloyed

.

What Is Alloy Steel?

alloy

and

steel

mean on their own.

alloy

is a mixture of two or more elements that, when mixed, retain metallic properties. It either mixes multiple more metals or metals with non‑metals, such as carbon or phosphorous. The mixture creates unique mechanical properties that the alloying elements don’t have on their own, such as corrosion resistance, increased tensile strength, or greater hardness.

is a basic mixture of iron and carbon with only trace amounts of other elements. Technically, carbon steel is an alloy since it mixes two elements, but it’s usually referred to as carbon steel – there is a

difference between carbon steel and steel alloys. Its makeup is mostly iron, but the carbon content is the significant structural component.

steel alloy

is a metal that adds alloying elements onto the basic steel structure. When they are added onto the carbon steel base, it creates different types of steel with added or changed mechanical properties.

A Note About Alloys

Characteristics of Common Alloy Elements

Boron

Carbon

Nitrogen

Aluminum

Silicon

Phosphorus

Sulfur

Titanium

Vanadium

Chromium

Manganese

Iron

Cobalt

Nickel

Copper

Selenium

Niobium

Molybdenum

Tantalum

Tungsten

Lead

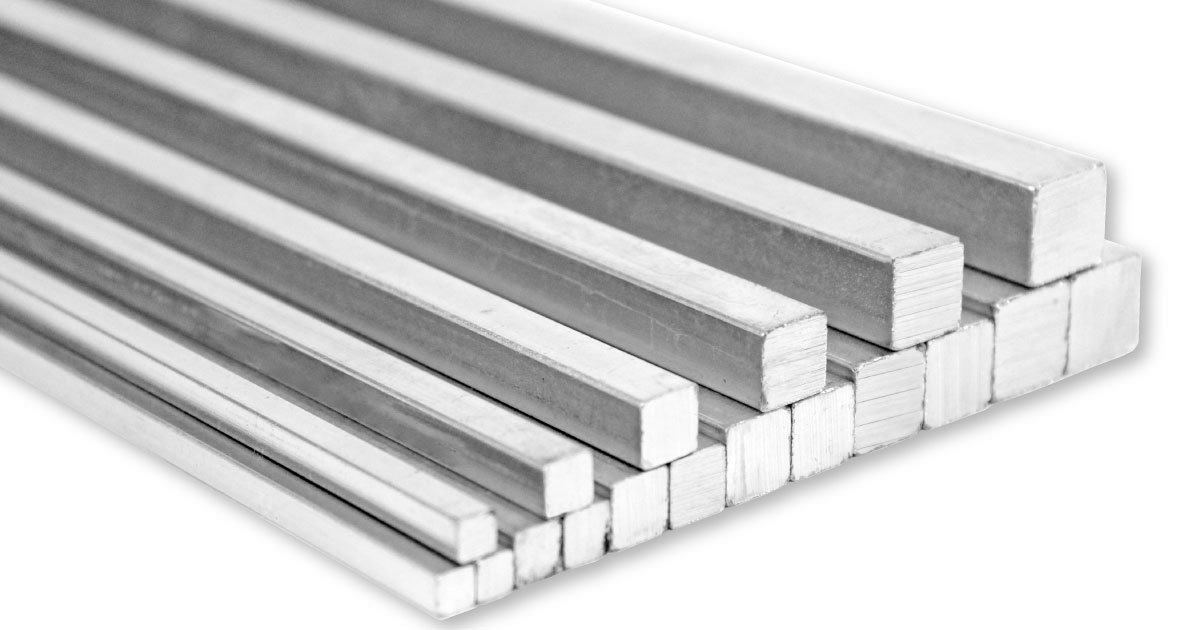

Common Types of Alloy Steel

keyed shafts.

- 1018 Steel

is a variety of low‑carbon steel, also known as mild steel. It contains a maximum of 0.2% carbon and smaller quantities of other elements. It offers an excellent compromise between strength, ductility, and machinability and is widely used in many applications. As low‑carbon steel, it can be case-hardened through carburization. It’s used to make fasteners like

rivet nuts and different types of

pins. - 1144 Steel

is medium-carbon steel with between 0.4 and 0.8% carbon, plus smaller quantities of manganese. It is relatively easy to machine and it can be heat‑treated to increase its hardness. - 304 and 316 Stainless Steel

are austenitic steels that contain chromium and nickel. 316 stainless steel also contains molybdenum, which improves its resistance to some types of corrosion. These stainless steels are widely used in screws and other types of corrosion‑resistant fasteners like

key stock,

pins, some

lifting and rigging hardware, and

hose clamps. - 410/416 Stainless Steel

are martensitic steels that contain between 11 and 12% chromium along with other elements including silicon, nickel, sulfur. 410 is a low-cost, heat treatable grade used for cutlery, screens, spring pins, turbine blades, and other non-severe corrosion applications. 416 offers excellent machinability and some magnetism, making it suitable for dowel pins, nuts, bolts, valve trim, and other fasteners. - 4140 Alloy Steel

, also called “chrome-moly” steel, is made up of chromium, manganese, and molybdenum. It is tough, ductile, and wear resistant, which makes it ideal for forging and responds well to heat treatments. As arguably the most common alloy steel available, it is used in almost all industries. - 8630 Alloy Steel

contains molybdenum, chromium, and nickel. It is tough yet ductile and offers good weldability and machining properties. 8630 is often used to make fasteners like

woodruff keys,

key stock, and

machine keys.

guide to steel alloy materials and attributes.

Non-Steel Metal Alloys

- Monel

is a nickel alloy. It is predominantly composed of nickel with copper and smaller amounts of iron and manganese. Monel is more expensive than steel, but it is highly resistant to corrosion and high temperatures. It is often used in applications in which components will frequently be in contact with corrosive materials or exposed to very high temperatures. It’s used to make certain types of

machine keys,

rivet nuts, and

grease fittings. - Brass

is an alloy of copper and zinc. It is softer and more ductile than steel while being resistant to corrosion, properties that make it desirable in some applications. It’s used to make certain types of rivet nuts, machine keys, and

pins.

The Bottom Line

custom manufacturing capabilities, don’t hesitate to

get in touch with our Sales team for more information.