Fastener Materials & Finishes: Corrosion & Strength

Fastener Materials & Finishes: Corrosion & Strength

Which material is best for nuts, bolts and screws? Does it matter if fasteners are galvanised or left bare to the elements? The short answer is: it depends!

Fasteners come in a variety of different materials, such as steel, brass, or even plastic. Finishes can include galvanised, plated and natural self colour. When choosing which fastener material or finish you need, consider what it will be used for. Will it be exposed to water or electricity? How strong does it need to be? Does it need to match aesthetically?

Here are some of the common fastener materials and finishes which we stock on our website. Read on to find out what they’re used for and their unique advantages.

Shop our full range of fasteners now

Types of Fastener Material: Stainless Steel, Nylon or Brass?

Browse our website and you’ll notice fasteners can be filtered by ‘Material’. Whether you need corrosion-resistant metals or lightweight plastic, find the best one for you below.

A2 & A4 Stainless Steel Fasteners

Stainless steel is a steel alloy, known for its resistance to corrosion. It is commonly used for cutlery, storage tankers and surgical instruments. We also stock stainless steel fasteners.

All stainless steel must contain at least 10% chromium, which helps it to resist corrosion. A2 (Type 304) and A4 (Type 316) are both very rust-resistant grades of stainless steel, but A2 can tarnish eventually. A4 is known as ‘marine grade’ stainless steel – it has a better level of corrosion resistance, making it ideal for use with chloride spray, solvents or chemicals.

When choosing stainless steel nuts, bolts and screws, consider their environment. A2 is often up to the job, but if you need industrial-strength resistance, A4 can be cost-effective. Like all metals, stainless steel is a relatively good conductor of electricity.

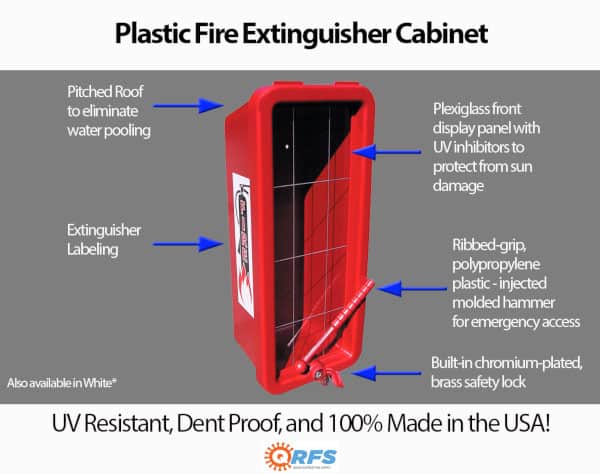

Nylon & Plastic Fasteners

Nylon fasteners are often used in electronics. They’re lightweight, resistant to chemicals and corrosion, and offer a high level of insulation and tensile strength. Plastic nuts, bolts and screws also melt rather than burn – making them ideal for projects where fire-resistance is a priority. However, they’re unsuitable for outdoor use and very high temperatures.

Click here to shop our range of nylon fasteners

Brass Fasteners

As a rule, you shouldn’t attach fasteners of different metals to each other, as this can cause further corrosion or a reaction between the two materials. If you’re working on a brass object, you should be using brass fasteners and fixings. We stock a selection of solid brass nuts, bolts and screws, so you can ensure your project is aesthetically and practically sound.

Types of Fastener Finish: An Extra Layer of Protection

There are more cost-effective options than using stainless steel for all your nuts, bolts and screws. Filter products using ‘Finish’ to add a layer of corrosion resistance or shine!

BZP (Bright Zinc Plated) Fasteners

Bright Zinc Plated is a finish applied to metals such as carbon steel, unalloyed steel and cast iron. Zinc is added using an electrical current during the production stage, leaving a shiny finish. It is the most common fastener finish and provides a thin layer of protection against rust and oxidation. However, BZP is not suitable for use in an outdoor environment.

HDG (Hot Dip Galvanised) Fasteners

Hot Dip Galvanised is a cost-effective finish to protect steel from corrosion. Fasteners are dipped in a bath of molten zinc, creating a weather-resistant – if not particularly attractive – layer. Galvanised nuts and bolts must be used with other galvanised fasteners, as a HDG finish increases their size. If the zinc is damaged, use a galvanising spray to re-protect.

Click here to shop our range of galvanized fasteners

Self Colour Steel Fasteners

Self colour steel is simply natural, uncoated mild steel – only a thin layer of oil is applied. It is often used in internal applications where corrosion resistance isn’t necessary. If suitably painted or treated, it can be used externally. As they’re not protected from the elements, self colour steel fasteners vary from a brand new silver to an oxidised almost-black.

Black Oxide Fasteners

Black oxide adds mild corrosion and abrasion protection, alongside an attractive black finish. It is ideal for environments where light-reflective metal could impair vision or cause fatigue. Black oxide is achieved by an oxidising chemical reaction – its resistance to corrosion can be boosted by adding an extra layer of oil or wax. It has barely any effect on conductivity.

GEOMET Fasteners

Geomet is an improved and modern version of the weather-resistant galvanised finish, which does not change the fastener size. It is comprised of aluminium and zinc flakes in a binder fluid, and does not contain chrome. A layer of Geomet gives a metallic silver appearance, conducts electricity well, and provides optimum anti-corrosion and friction performance.

Yellow Zinc Plating Fasteners

Yellow zinc plating is similar to bright zinc plating (BZP), but adds an iridescent golden sheen. Like BZP, it is applied using a current of electricity and does not increase the fastener size like galvanisation. It also offers some corrosion resistance, but should not be used outdoors or underwater. Yellow zinc is commonly used in the car and automotive industry.

Questions about fastener materials or finishes? Call us on 0114 263 4422 or email sales@shop4fasteners.co.uk.