Exploring the Benefits of Progressive Cavity Oem Spare Parts

In the world of industrial machinery, the importance of reliable components cannot be overstated. Among these components, progressive cavity pumps play a critical role in various applications, from wastewater treatment to food processing. To ensure the optimal performance of these pumps, the use of progressive cavity OEM spare parts is essential. This article delves into the numerous benefits of utilizing OEM spare parts, highlighting their significance in enhancing efficiency, reducing costs, and improving overall operational reliability.

Understanding Progressive Cavity Pumps

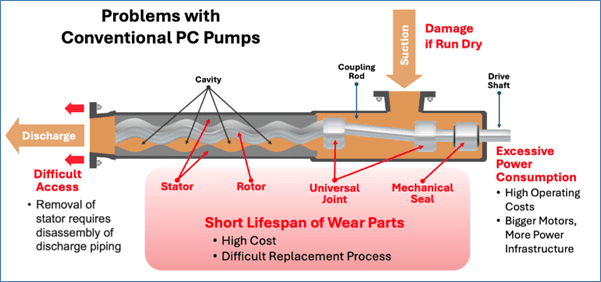

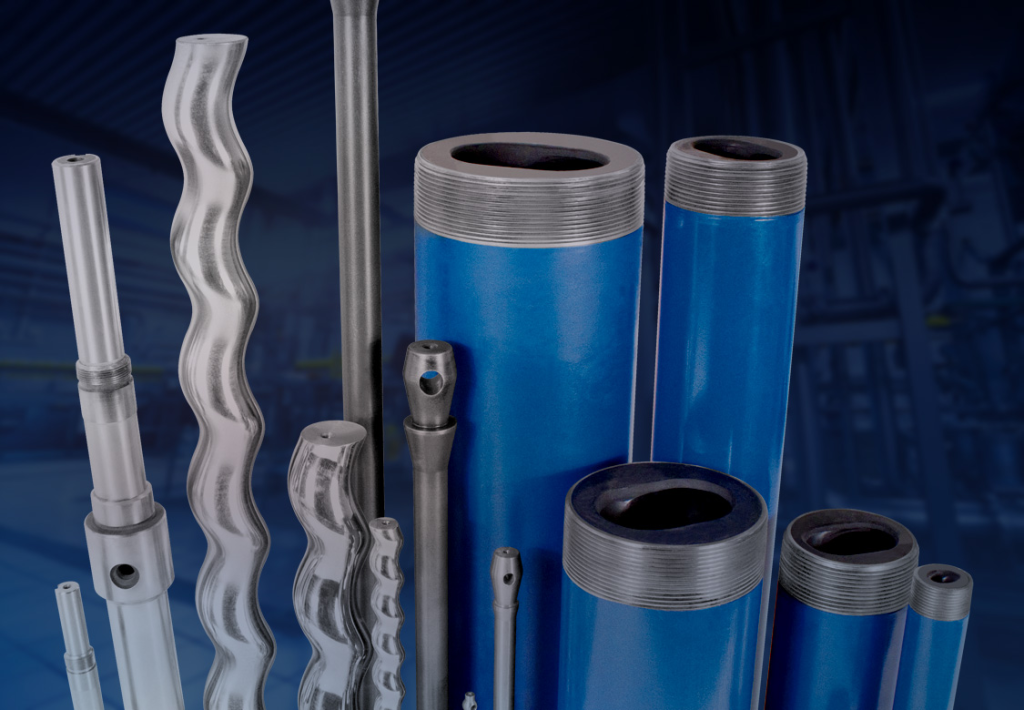

Progressive cavity pumps are characterized by their unique design, which allows them to move fluids smoothly and steadily. They are especially effective for transferring viscous liquids and slurries, making them a preferred choice in many industries. The performance of these pumps is heavily reliant on the quality of their components. Using OEM spare parts ensures that the integrity and functionality of the pump are maintained, leading to enhanced performance.

Advantages of Progressive Cavity OEM Spare Parts

When considering spare parts for your progressive cavity pumps, opting for OEM components offers several distinct advantages:

- Quality Assurance: OEM spare parts are manufactured according to the specifications set by the original manufacturer. This guarantees a level of quality and reliability that is often unmatched by generic alternatives.

- Perfect Compatibility: OEM parts are designed to fit seamlessly with existing equipment. This compatibility minimizes the risk of malfunctions and operational inefficiencies that can arise from using ill-fitting components.

- Extended Lifespan: The durability of OEM parts contributes to the overall longevity of the equipment. By using high-quality components, you can reduce the frequency of replacements and repairs.

- Warranty Protection: Many manufacturers provide warranties for their equipment, which often stipulate the use of OEM parts. Using these components can help protect your warranty, ensuring that you are covered in case of any issues.

Cost-Effectiveness of OEM Spare Parts

While the initial investment in OEM spare parts may seem higher than that of generic options, the long-term savings can be substantial. Here are some ways that progressive cavity OEM spare parts contribute to cost-effectiveness:

1. Reduced Downtime

Using OEM parts minimizes the likelihood of equipment failure. When pumps operate efficiently, downtime is significantly reduced. This means that production processes can continue without interruption, leading to increased productivity and profitability.

2. Lower Maintenance Costs

OEM spare parts require less frequent replacements and repairs, which translates to lower maintenance costs. Investing in quality components upfront can save you money in the long run by minimizing the need for ongoing repairs.

3. Enhanced Efficiency

The superior performance of OEM parts leads to enhanced efficiency in operations. When equipment runs smoothly, it consumes less energy and resources, resulting in lower operational costs.

4. Improved Safety

Reliable equipment is safer for operators and the surrounding environment. By using OEM parts, you reduce the risk of malfunctions that could lead to accidents or hazardous situations, thereby protecting your workforce and assets.

Best Practices for Utilizing OEM Spare Parts

To maximize the benefits of progressive cavity OEM spare parts, consider the following best practices:

- Regular Maintenance: Schedule routine maintenance checks to monitor the condition of your pumps and their components. Regular inspections can help identify wear and tear before they lead to significant issues.

- Keep an Inventory: Maintaining an inventory of essential OEM spare parts ensures that you have immediate access to replacements when needed. This proactive approach can help minimize downtime during critical operations.

- Train Your Team: Invest in training for your staff to ensure they understand the importance of using OEM parts and how to properly maintain progressive cavity pumps. Knowledgeable personnel can effectively manage equipment and recognize potential issues early.

- Work with Reputable Suppliers: Establish relationships with trusted suppliers of OEM parts. A reliable supplier can provide valuable insights into product availability, pricing, and upcoming innovations.

- Document Maintenance Activities: Keeping detailed records of maintenance activities and part replacements can help track performance trends over time. This documentation can inform future purchasing decisions and maintenance schedules.

Conclusion

The benefits of utilizing progressive cavity OEM spare parts extend far beyond immediate performance enhancements. By prioritizing quality, compatibility, and reliability, businesses can achieve significant long-term savings, improve operational efficiency, and ensure the safety of their equipment and personnel. Investing in OEM components is not just a choice; it is a strategic decision that can lead to sustained success in a competitive industrial landscape. By understanding and embracing these benefits, organizations can better position themselves for future growth and operational excellence.