How to Choose the Right Cavity Pump Manufacturer

Choosing the right progressive cavity pump manufacturer is essential for ensuring the efficiency and reliability of your operations. Progressive cavity pumps are widely used in various industries, including wastewater treatment, food processing, and chemical manufacturing. Selecting a suitable manufacturer involves several critical considerations. This article will guide you through the key factors to consider when making your choice.

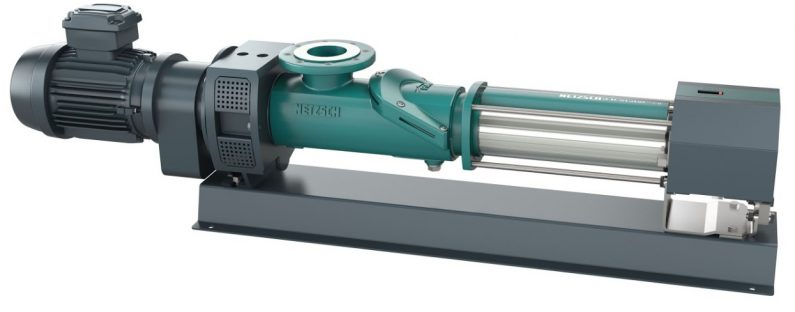

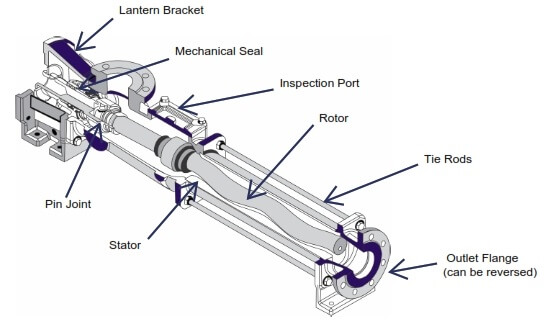

Understanding Progressive Cavity Pumps

Before diving into the selection process, it’s important to understand what progressive cavity pumps are and their applications. These pumps consist of a helical rotor that moves fluid through a series of cavities, providing a smooth and continuous flow. They are particularly effective for handling viscous fluids, slurries, and shear-sensitive materials.

Key Factors to Consider

When evaluating potential progressive cavity pump manufacturers, keep the following factors in mind:

1. Experience and Reputation

- Industry Experience: Look for a manufacturer with extensive experience in producing progressive cavity pumps. A company that has been in the industry for many years is likely to have a better understanding of the challenges and requirements specific to different applications.

- Customer Reviews: Research customer testimonials and case studies. Positive feedback from other users can provide insight into the manufacturer’s reliability and product performance.

2. Quality of Products

- Material Selection: High-quality materials are crucial for the durability and efficiency of cavity pumps. Ensure the manufacturer uses materials that can withstand the specific conditions of your application, such as corrosive substances or extreme temperatures.

- Manufacturing Standards: Check if the manufacturer adheres to international quality standards. Certifications such as ISO can indicate a commitment to maintaining high-quality production processes.

3. Customization Options

- Tailored Solutions: Different industries have unique requirements. A good manufacturer should offer customization options to tailor the pumps to your specific needs, whether it’s sizing, materials, or features.

- Technical Support: Assess the level of technical support offered. A manufacturer that provides engineering assistance and consultation can help you choose the right pump configuration for your application.

4. After-Sales Service

- Warranty and Support: Evaluate the warranty options provided. A comprehensive warranty can protect your investment and give you peace of mind.

- Maintenance Services: Inquire about maintenance and repair services. A manufacturer that offers ongoing support can help you prolong the life of your pumps and ensure optimal performance.

5. Cost and Value

- Budget Considerations: While price is an important factor, it should not be the sole criterion. Look for a manufacturer that offers a balance between cost and quality. Sometimes, investing a bit more upfront can save you money in the long run through reduced maintenance and downtime.

- Total Cost of Ownership: Consider the total cost of ownership, which includes initial purchase price, maintenance costs, and energy consumption. A more efficient pump may have a higher initial cost but can lead to lower operational expenses.

Researching Potential Manufacturers

Once you have identified the key factors, it’s time to research potential manufacturers. Here are some steps to help you in your search:

1. Online Research

Utilize online resources to gather information about various manufacturers. Visit their websites to learn about their product offerings, company history, and customer feedback.

2. Industry Events and Trade Shows

Attending industry events and trade shows can provide opportunities to meet manufacturers in person. These gatherings often feature product demonstrations and allow you to ask questions directly.

3. Consult with Industry Peers

Networking with peers in your industry can yield valuable recommendations. Colleagues who have experience with specific manufacturers can offer insights that may not be available through online research.

Conclusion

Choosing the right cavity pump manufacturer is a critical decision that can significantly impact your operations. By considering factors such as experience, product quality, customization options, after-sales service, and overall value, you can make an informed choice. Conduct thorough research and consult with industry experts to ensure that you partner with a manufacturer that meets your specific needs. With the right manufacturer by your side, you can enhance the efficiency and reliability of your pumping systems for years to come.